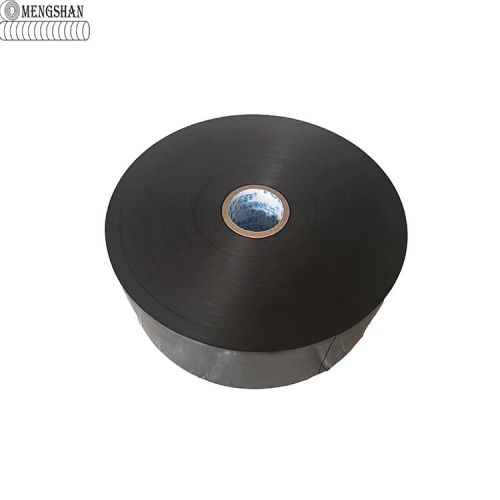

PE Anticorrosion wrap tape with 183m roll

PE Anticorrosion wrap tape

Product Description

The MENG SHAN 980,955 PE Anticorrosion wrap tape with 183m roll is a multilayer system used for the protection of steel pipelines. MENG SHAN 1019,1027, Liquid Adhesives can be used as primers for this system.In addition to serving as primers, these liquid adhesives themselves represent an anticorrosion layer and provide a uniformly smooth contact surface to promote high adhesion of the coating system to the pipe. They are designed for machine or brush application and formulated with stress-corrosion cracking inhibitors. The Anti-Corrosion layer MENG SHAN 980 is engineered to assure a high bond to the primed surface with excellent conformability characteristics. The mechanical protection layer MENG SHAN 955,achieves a complete bond to the MENG SHAN 980 inner layer, providing maximum handling and in-service protection for the coating system. The adhesives in these and all MENG SHAN tape systems contain proven anti-microbial additives.The MENG SHAN 980/955 can also be used for ductile iron pipes, in this case the use of 1027 primer is recommended.

PE Anticorrosion wrap tape Features

|

-Resistant to soil stress - Excellent adhesion to pipe and self -Low cathodic protection -Long-term in-ground performance - Serve for low-high temperatures |

- Cold applied -Uniform coating thickness -Compatible with all pipe diameters and generic plant coating systems -Qualified ASTM D1000,AWWA C 214,EN 12068 standards |

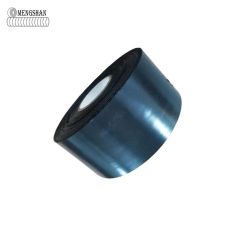

Structure

|

Backing : Special blend of stabilized polyethylene |

|

Adhesive : Butyl rubber and Adhesion Promoting Resins |

|

Color: Black |

Properties

|

Product Properties |

Test method |

Typical Value |

|||

|

MENGSHAN 980-15 |

MENGSHAN 980-20 |

MENGSHAN 980-25 |

MENGSHAN 980-30 |

||

|

Total Thickness |

|

15mil(0.381mm) |

20mil(0.508mm) |

25mil(0.635mm) |

30mil(0.762mm) |

|

Backing of PE film |

|

9 mils(0.229 mm) |

12mil(0.305mm) |

13mil(0.330mm) |

10mil(0.254mm) |

|

Butyl Rubber Adhesive |

|

6 mils(0.152 mm) |

8mil(0.203mm) |

12mil(0.305mm) |

20mil(0.508mm) |

|

Tensile Strength |

ASTM D1000 |

40 N/cm |

55 N/cm |

62 N/cm |

70 N/cm |

|

Elongation |

ASTM D1000 |

300% |

330% |

350% |

400% |

|

Peel Adhesion to Primed Steel |

ASTM D1000 |

24.5 N/cm |

25 N/cm |

26.5 N/cm |

30 N/cm |

|

Water Vapor Transmission Rate |

ASTM E 96 |

0.10g/m2 |

0.10g/m2 |

0.09g/m2 |

0.08g/m2 |

|

Water absorption after 1 day,At+23℃ |

ASTM D570 |

0.10% |

0.10% |

0. 08% |

0. 06% |

|

Volume Resistivity |

ASTM D 257 |

2.0 x 1015 ohm.cm |

2.5 x 1015 ohm.cm |

2.5 x 1015 ohm.cm |

2.5 x 1015 ohm.cm |

|

Dielectric Strength |

ASTM D149 |

30 kV |

35 kV |

42kv |

43kv |

https://www.pipe-wrap-tape.com/resources/how-long-does-it-take-the-liquid-rubber.html