Materials for printing press rollers

Printing press rollers are typically made of a range of materials, including rubber, polyurethane, and other polymers. The specific material used will depend on the specific application and requirements of the roller.

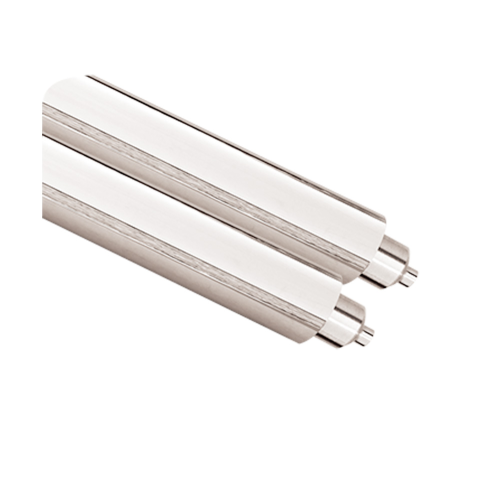

Product Description

What materials are printing press rollers made of?

Printing press rollers are typically made of a range of materials, including rubber, polyurethane, and other polymers. The specific material used will depend on the specific application and requirements of the roller.

For example, rubber rollers are commonly used for water-based inks, while polyurethane rollers are often used for solvent-based inks. Polymer rollers are also used, as they offer a combination of durability, flexibility, and resistance to various types of inks and solvents.

Some rollers may also have a metal core, which provides added strength and stability, while others may have a foam core, which offers additional cushioning and shock absorption.

In general, the choice of material will depend on factors such as the type of ink or solvent being used, the type of printing process, and the specific requirements of the printing press and its environment.

Hebei DaYa Rubber Roller Co., Ltd. has strong production capability and professional R&D ability, and a whole set of producing and testing equipment: a mixing mill, filter separator, rubber roller winding machine, Polyurethane pouring machine, plate vulcanizing press, numerical universal cylindrical grinding, digital controlled lathe, planer type milling machine, hard-support bearing balancing machine, rubber tension tester, etc. to meet the demand of production and testing.

The company has also gained the whole quality management system: ISO 9001: Quality Management System Certification in 2000 and the consecutive re-certificate have been passed; the 2008/ISO 9001: Quality Management System Certification in 2008 has passed in 2010.

Through constant technology improvement, my company’s biggest processing diameter is 2000mm, the longest processing length is 8000mm, and rubber hardness (Shore A): is 20-100°.