Standard Five-layer Sintered Mesh

Standard Five-layer Sintered Mesh

Product Description

China leading 5-layer Sintered Wire Mesh Manufacturer

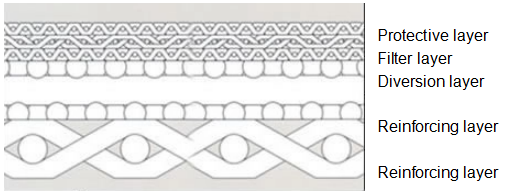

Dashang 5-layer sintered wire mesh has a standard 5-layer structure: protective layer, filtration layer, separation layer, and support layer. Each layer has a specific function. The protective layer prevents external damage, the filtration layer is responsible for capturing particles, the separation layer separates materials and liquids, and the support layer ensures the stability of the overall structure.

This design ensures that the filter material has both uniform and stable filtration accuracy and high strength and rigidity, can withstand a certain pressure, and ensure the effectiveness and safety of the filtration process.

Dashang Wire Mesh is committed to the research and improvement of standard five-layer sintered mesh, meeting the filtration accuracy requirements of 1-300 microns, and improving industry standards and technical levels. When producing standard five-layer sintered mesh, we focus on the reasonable configuration and optimization between the layers to improve the performance of the final product.

Standard 5 layer sintered wire mesh layer structure.

Production of standard five-layer sintered mesh

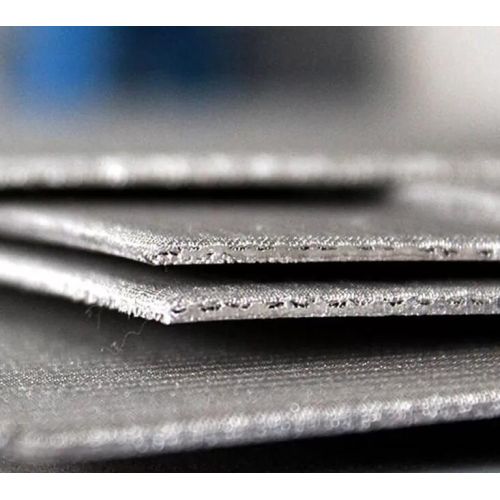

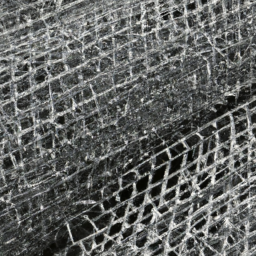

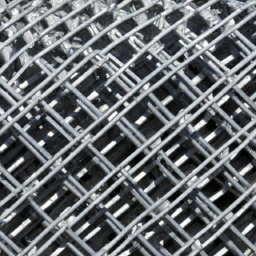

The production of standard five-layer sintered mesh involves complex processes, including material selection, weaving, stacking and sintering. Stainless steel is a commonly used material because of its corrosion resistance and high strength.

Performance and Advantages

-

Good strength and rigidity (high strength): good mechanical strength and compressive strength, good processing, welding and assembly performance, easy to use;

-

Uniform and stable precision (high precision): uniform and consistent filtration performance at all filtration accuracies, and the mesh size remains unchanged during use;

-

Widely used in various environments (heat resistance): can be used for filtration in temperature environments from -200℃ to 600℃ and in acidic and alkaline environments;

-

Excellent cleaning performance: excellent countercurrent cleaning effect, reusable, and long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

-

Suitable for laser cutting

-

Supports welding, cutting, punching, bending and stretching

-

Suitable for high viscosity environments

Application of Standard five-layer sintered mesh

Standard five-layer sintered mesh is widely used in many occasions where precision filtration is required, such as chemical, pharmaceutical, food processing and other industries. Because sintered mesh has high mechanical strength and compressive strength, excellent filtering performance and cleaning performance, it can be widely used in the precision filtration of various hydraulic oils and lubricating oils in the machinery industry, and the precision filtration of various polymer melts in the chemical fiber film industry. Filtration and purification of various high-temperature corrosive liquids in the petrochemical industry, filtration, washing and drying of materials in the pharmaceutical industry, and gas homogenization in the powder industry.