0Cr27Al5Ti FeCrAl Alloy

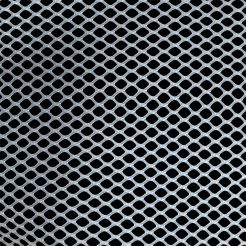

0Cr27Al5Ti (Х27Ю5Т) is a kind of high electric resistance FeCrAl alloy adding Ti 0.15~0.40% for using at temperature up to 1350℃.We mainly produce resistance wire fecral, fecral strips, fecral alloys sheet, fecral ribbon, fecral wire mesh, etc.

Product Description

FeCrAl 275Ti/ 0Cr27Al5Ti

0Cr27Al5Ti (Х27Ю5Т) is a kind of high electric resistance FeCrAl alloy adding Ti 0.15~0.40% for using at temperature up to 1350℃.We mainly produce resistance wire fecral, fecral strips, fecral alloys sheet, fecral ribbon, fecral wire mesh, etc.

Chemical composition according to GOST 10994-74

|

Fe |

C |

Si |

Mn |

Ni |

S |

P |

Cr |

Ce |

Ti |

Al |

Ba |

Ca |

- |

|

Bal. |

≤ 0.05 |

≤ 0.6 |

≤ 0.3 |

≤ 0.6 |

≤ 0.015 |

≤ 0.02 |

26-28 |

≤ 0.1 |

0.15-0.4 |

5-5.8 |

≤ 0.5 |

≤ 0.1 |

Ca, Ce - calculation |

Temperature factors of resistivity

|

|

Values of the correction factor R0 / R20 at heating temperature, ℃ |

||||||||||||||

|

|

20 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

|

0Cr27Al5Ti |

1, 000 |

1, 002 |

1, 005 |

1, 010 |

1, 015 |

1, 025 |

1, 030 |

1, 033 |

1, 035 |

1, 040 |

1, 040 |

1, 041 |

1, 043 |

1, 045 |

- |

Mechanical and electrical properties of the alloy

|

Alloy grade |

Resistivity ρ, μOhm * m |

Tensile strength, N / mm2 (kgf / mm2), no more |

Elongation, %, not less |

Test temperature, ℃ |

Continuous service life, h, not less |

Density |

|

0Cr27Al5Ti |

1.37- 1.47 |

780 ( 80) |

10 |

1300 |

80 |

7.19g/cm³ |

• Cold-drawn wire GOST 12766.1- 90

• Cold-rolled strip GOST 12766.2- 90

• Hot-rolled round bar GOST 2590-2006

• Packing GOST 7566-2018

0Cr27Al5Ti wire condition

Limit wire diameters, 0.1 - 10 mm:

0.1 - 1.2 mm - light surface, coil

1.2 - 2 mm - light surface, coil

2 - 10 mm - oxidized or etched surface, coil

* The wire is made in a soft heat-treated state.

Limit deviations correspond to qualifications (GOST 2771):

js 9 - for diameters from 0.1 to 0.3 mm inclusive,

js 9 - for diameters of St. 0.3 to 0.6 mm inclusive,

js 10 - for diameters of St. 0.6 to 6.00 mm inclusive,

js 11 - for diameters of St. 6.00 to 10 mm inclusive,

* By agreement between the consumer and the manufacturer, wire is made of other diameters.

NAMIMAL VALUES OF ELECTRIC RESISTANCE 1 m WIRE, Ohm / m

|

Diameter( mm) |

cross-sectional area(mm²) |

Ohm / m |

Diameter, (mm) |

cross-sectional area(mm²) |

Ohm / m |

Diameter (mm) |

cross-sectional area(mm²) |

Ohm / m |

Diameter (mm) |

cross-sectional area(mm²) |

Ohm / m |

|

0.1 |

0.00785 |

- |

0.3 |

0.0707 |

- |

0.9 |

0.636 |

2.23 |

2.6 |

5.31 |

0.267 |

|

0.105 |

0.00865 |

- |

0.32 |

0.0804 |

- |

0.95 |

0.708 |

2.00 |

2.8 |

6.15 |

0.231 |

|

0.11 |

0.00950 |

- |

0.34 |

0.0907 |

- |

1 |

0.785 |

1.81 |

3 |

7.07 |

0.201 |

|

0.115 |

0.0104 |

- |

0.36 |

0.102 |

- |

1.06 |

0.882 |

1.61 |

3.2 |

8.04 |

0.177 |

|

0.12 |

0.0113 |

- |

0.38 |

0.113 |

- |

1.1 |

0.950 |

1.49 |

3.4 |

9.07 |

0.156 |

|

0.13 |

0.0133 |

- |

0.4 |

0.126 |

- |

1.15 |

1.04 |

1.37 |

3.6 |

10.2 |

0.139 |

|

0.14 |

0.0154 |

- |

0.42 |

0.138 |

- |

1.2 |

1.13 |

1.26 |

3.8 |

11.3 |

0.126 |

|

0.15 |

0.0177 |

- |

0.45 |

0.159 |

- |

1.3 |

1.33 |

1.07 |

4 |

12.6 |

0.113 |

|

0.16 |

0.0201 |

- |

0.48 |

0.181 |

- |

1.4 |

1.54 |

0.922 |

4.2 |

13.8 |

0.103 |

|

0.17 |

0.0227 |

- |

0.5 |

0.196 |

7.25 |

1.5 |

1.77 |

0.802 |

4.5 |

15.9 |

0.0893 |

|

0.18 |

0.0254 |

- |

0.53 |

0.221 |

6.43 |

1.6 |

2.01 |

0.707 |

4.8 |

18.1 |

0.0785 |

|

0.19 |

0.0283 |

- |

0.56 |

0.246 |

5.77 |

1.7 |

2.27 |

0.626 |

5 |

19.6 |

0.0723 |

|

0.2 |

0.0314 |

- |

0.6 |

0.283 |

5.02 |

1.8 |

2.54 |

0.559 |

5.3 |

22.1 |

0.0644 |

|

0.21 |

0.0346 |

- |

0.63 |

0.312 |

4.55 |

1.9 |

2.83 |

0.500 |

5.6 |

24.6 |

0.0577 |

|

0.22 |

0.0380 |

- |

0.67 |

0.352 |

4.02 |

2 |

3.14 |

0.452 |

6.1 |

29.2 |

0.0486 |

|

0.24 |

0.0452 |

- |

0.7 |

0.385 |

3.69 |

2.1 |

3.46 |

0.410 |

6.3 |

31.2 |

- |

|

0.25 |

0.0491 |

- |

0.75 |

0.442 |

3.21 |

2.2 |

3.80 |

0.374 |

6.7 |

35.2 |

- |

|

0.26 |

0.0531 |

- |

0.8 |

0.502 |

2.82 |

2.4 |

4.52 |

0.314 |

7 |

38.5 |

- |

|

0.28 |

0.0615 |

- |

0.85 |

0.567 |

2.50 |

2.5 |

4.91 |

0.289 |

7.5 |

44.2 |

- |

* Deviation of electrical resistance of 1 m of wire from the nominal should not exceed ± 5%

0Cr27Al5Ti strip condition

Limit strip thicknesses, 0.05 - 3.2 mm:

|

Belt thickness, mm |

Maximum deviation in thickness, mm |

Limit deviation in width with the width of the strip, mm |

Width strip, mm |

Length, m, not less |

|

|

up to 100 incl. |

St. 100 |

||||

|

no more |

|||||

|

0, 10; 0, 15 |

±0, 010 |

- 0, 3 |

- 0, 5 |

6- 200 |

40 |

|

0, 20; 0, 22; 0, 25 |

±0, 015 |

- 0, 3 |

- 0, 5 |

6- 250 |

40 |

|

0, 28; 0, 30; 0, 32; 0, 35; 0, 36; 0, 40 |

±0, 020 |

- 0, 3 |

- 0, 5 |

6- 250 |

40 |

|

0, 45; 0, 50 |

±0, 025 |

- 0, 3 |

- 0, 5 |

6- 250 |

40 |

|

0, 55; 0, 60; 0, 70 |

±0, 030 |

|

|

6- 250 |

|

|

0, 80; 0, 90 |

±0, 035 |

- 0, 4 |

- 0, 6 |

|

|

|

1, 0 |

±0, 045 |

|

|

|

|

|

1, 1; 1, 2 |

±0, 045 |

|

|

|

20 |

|

1, 4; 1, 5 |

±0, 055 |

- 0, 5 |

- 0, 7 |

10- 250 |

|

|

1, 6; 1, 8; 2, 0 |

±0, 065 |

|

|

|

|

|

2, 2 |

±0, 065 |

|

|

|

|

|

2, 5; 2, 8; 3, 0; 3, 2 |

±0, 080 |

- 0, 6 |

—— |

20-80 |

10 |

The crescent shape of the strip for 1 m of length should not exceed:

10 mm - for strip less than 20 mm wide;

5 mm - for strip 20-50 mm wide;

3 mm - for strip more than 50 mm wide.

* The deviation of the electrical resistance of 1 m of the strip from the nominal should not exceed ± 5% - for strip of high quality and ± 7% - for strip of normal quality.

* The variation of the electrical resistance of the strip within one roll does not exceed 4%.

We provide customized services, and the size and packaging of products can be customized according to customer needs. The production of our FeCrAl alloy products strictly follows the national standards. If customers have special requirements, we can also produce according to the national standards of customers.please contact us if you have any needs, we will give you good quality products and competitive price.