Hydraulic Molding Machine

Hydraulic Molding Machine

Product Description

The forming machine is a special equipment for forming the white area of lost foam. It is based on the raw polystyrene (EPS) or copolymerization material. After the raw material is treated by foaming, drying and curing, the EPS and the polymer beads are sent into the mold automatically by this machine, and then the steam heating is formed. After cooling and setting the mold, the foam plastic products are automatically separated from the mold.

Product Structure

1. foam molding machine support

2. The upper frame

3. guide column

4. The lower frame

5. hydraulic system

6. Control system can be selected according to customer requirements (Delta, SIEMENS).

Main Function and Advantages

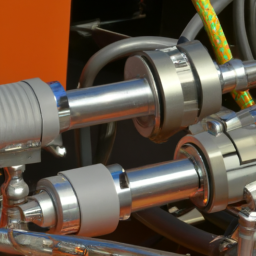

1. The machine structure adopts the welding structure and is dealt with efficiently The four guide pillars are vertical layout. The precision is stable and reliable.The main components of this machine are international well-known brand. They form excellent engine-electric-pneumatic integral system. It makes the machine with the advantages of reliable action, low energy consumption, long life, high production efficiency.

2. The machine is controlled by the programmable controller (PLC). The touch type man-machine interface can set the process parameters, and the built-in program can be applied to the molding process of most foam products.

3. The computer memory stores commonly used foam density relative parameters, convenient for subsequent use.

4. The machine uses pressure heating control mode. Users can adjust according to needs.

5. Hydraulic driven, with differential circuit and smooth operation.