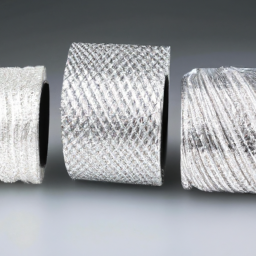

Stators and Rotors

Product origin: guangdong Specification: ODФ260xIDФ185

Product Description

Rotor And Stator in Motor

Introduction

Are you looking for high-quality rotor and stator in motor for your industrial applications? Look no further! At , we offer a wide range of top-notch stators and rotors that are engineered to meet the most demanding requirements. If you are interested in our rotor and stator in motor, please as soon as possible.

What are Stators and Rotors?

A in motor are integral components of electric motors and generators. The stator is the stationary part that houses the windings, while the rotor is the rotating part that carries the magnet. Together, they create the electromagnetic field necessary for the conversion of electrical energy into mechanical energy and vice versa.

The Functionality of Stators and Rotors

The functionality of rotor and stator in motor revolves around the principles of electromagnetism. When an electrical current passes through the windings in the stator, a magnetic field is created. This magnetic field interacts with the magnetic field of the rotor, resulting in a force that causes the rotor to rotate. The rotation of the rotor then generates mechanical energy or induces an electrical current, depending on the application.

Applications of Stators and Rotors

The applications of rotor and stator in motor is diverse and widespread across various industries. Let's explore some of the common applications:

Electric Motors:

Rotor and stator in motor is key components in electric motors used in industries such as automotive, aerospace, and manufacturing. They power everything from fans and pumps to conveyor systems and heavy machinery.

Generators:

In power generation facilities, stators and rotors play a vital role in producing electricity. They are utilized in hydroelectric, wind, and thermal power plants to convert mechanical energy into electrical energy.

Pumps and Compressors:

Stators and rotors find extensive use in pumps and compressors, enabling the transfer of fluids or gases in various industrial processes.

Electric Vehicles:

The rising popularity of electric vehicles has increased the demand for efficient stators and rotors. These components are crucial for the propulsion system, delivering power and torque to drive the wheels.

Specification

| Describe | Custom stamped stator and rotor cores |

| Types Of | Stator and rotor Core |

| Application | AC servo motor |

| Processing | stamping |

| Material | Silicon steel |

| Weight Range | 0.5-100Kg |

| design support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to AC servo motors

Advantages of High-Quality Stators and Rotors

Investing in high-quality stators and rotors from offers several advantages. Some of the key benefits include:

Enhanced Efficiency:

High-quality stators and rotors are designed to minimize energy loss and maximize efficiency, resulting in cost savings and improved performance.

Reliability and Durability:

Premium stators and rotors are manufactured using top-grade materials and advanced techniques, ensuring long-lasting performance and resistance to wear and tear.

Precise Engineering:

Each stator and rotor undergoes stringent quality checks, guaranteeing precise engineering and adherence to industry standards.

Optimized Performance:

Well-designed stators and rotors optimize the overall performance of electric motors and generators, enabling smooth operations and increased productivity.

Our service

1. Have a strong R&D team.

2. Quickly respond to your inquiries and feedback.

3, good quality, strict quality control.

4. Professional after-sales team.

Rotor and Stator in Motor: Efficient Components for Power and Performance

Are you in need of reliable and efficient components for your motor applications? Look no further than . As a leading manufacturer specializing in high-speed stamping and insulation coating of motor cores, we pride ourselves on delivering top-notch products to meet the most demanding requirements.

Introducing CHME Components Co., Ltd.

At , we have been a trusted name in the automobile supporting industry since 2012. With our ISO9001 and IATF16949 certifications, you can trust in the quality and reliability of our products. We have invested in state-of-the-art machinery and molds, allowing us to provide a comprehensive range of stamped parts for motors of various sizes. Our commitment to rapid response and thoughtful service sets us apart in the industry, ensuring that your needs are met promptly and efficiently.

Rotor and Stator: Powerhouses of Motor Efficiency

The rotor and stator are integral components of electric motors, working together to convert electrical energy into mechanical energy. Let's delve into the features and benefits of our rotor and stator offerings:

1. Customization for Your Unique Requirements

At CHME Components Co., Ltd., we understand that every motor application is unique. That's why our rotor and stator products are fully customizable. You can provide us with your drawings and dimensions, and our skilled engineers will craft components that precisely fit your specifications. With our expertise in high-speed stamping and insulation coating, you can trust us to deliver tailored solutions that meet your needs.

2. Reliable Quality for Optimal Performance

We take pride in our commitment to delivering products of the highest quality. Our rotor and stator offerings undergo rigorous quality control measures to ensure reliability and durability. With our advanced manufacturing processes and strict adherence to industry standards, you can rely on our components to perform optimally, even in demanding applications.

3. Efficient Design for Enhanced Performance

Efficiency is crucial in motor applications, and our rotor and stator components are designed to deliver just that. Our engineers utilize cutting-edge technology and precision engineering to create components that minimize energy loss and maximize performance. By choosing our rotor and stator solutions, you can achieve improved energy efficiency, reduced operational costs, and enhanced overall performance.

4. Cost-Effective Solutions for Your Business

At CHME Components Co., Ltd., we understand the importance of cost savings for your business. Our rotor and stator offerings provide affordable solutions without compromising on quality or performance. With our competitive pricing and efficient manufacturing processes, you can save costs without sacrificing the reliability and functionality of your motors. We believe in delivering value to our customers and helping you achieve your business goals.

5. Expertise in Engineering and Processing

Our mission at CHME Components Co., Ltd. is to help our customers tackle the toughest challenges in engineering and processing. With years of experience in the industry, our team of experts is equipped with the knowledge and skills to provide innovative solutions for your motor core needs. Whether you require assistance in design optimization, material selection, or customization, we are here to support you every step of the way.

Partner with CHME Components Co., Ltd. for Superior Rotor and Stator Solutions

When it comes to powering your motors, the rotor and stator are crucial components that can significantly impact performance and efficiency. By choosing CHME Components Co., Ltd. as your trusted partner, you gain access to high-quality, customizable rotor and stator solutions tailored to your requirements.

Our commitment to excellence, reliable quality, and cost-effective solutions sets us apart in the industry. Let us help you overcome your engineering challenges and take your motor applications to new heights. to discuss your rotor and stator needs, and experience the CHME Components Co., Ltd. difference.

Frequently Asked Questions (FAQs)

Q1: What materials are commonly used in the manufacturing of stators and rotors?

A1: Stators are typically made of laminated electrical steel, while rotors are often constructed from magnetic materials such as iron, steel, or permanent magnets.

Q2: Can I customize stators and rotors according to my specific requirements?

A2: Absolutely! At CHME Components, we offer customization options to meet your unique needs. Our expert team can assist you in designing and manufacturing stators and rotors tailored to your specifications.

Q3: How do I determine the appropriate size and specifications for stators and rotors?

A3: Selecting the right size and specifications for stators and rotors depends on factors such as power requirements, rotational speed, and application. Our knowledgeable team can guide you through the selection process, ensuring optimal performance.

Q4: Are stators and rotors interchangeable between different motor brands?

A4: While there may be some compatibility between motor brands, it is crucial to consult the manufacturer's guidelines and specifications. Our team can help you identify suitable stators and rotors based on your specific motor requirements.

Q5: How often should stators and rotors be inspected for maintenance?

A5: Regular inspection and maintenance of stators and rotors are essential for ensuring optimal performance and extending their lifespan. The frequency of inspections may vary depending on usage and environmental conditions.

Q6: What are the factors that affect the efficiency of stators and rotors?

A6: Several factors can impact the efficiency of stators and rotors, including design, materials used, operating conditions, and maintenance practices. Choosing high-quality components and implementing proper maintenance can maximize efficiency.