sintering process in metallurgy

Sintering Process in Metallurgy: Enhancing Strength and Durability.

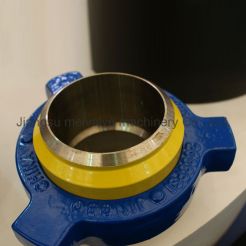

Product Description

Sintering Process in Metallurgy: Enhancing Strength and Durability.

Sintering is a revolutionary process in metallurgy that transforms simple metal powders into strong, durable, and flawless products. With our cutting-edge technology, we bring you an innovative solution that combines the power of science with the art of manufacturing.

Key Features:

1. Advanced Powder Consolidation: Our sintering process utilizes advanced powder consolidation techniques, ensuring a uniform distribution of particles. By heating the metal powders to a controlled temperature, they bond together, forming a dense and rigid structure. This results in enhanced mechanical properties, such as increased strength and improved wear resistance.

2. Exceptional Thermal Homogeneity: Our sintering technology facilitates the proper diffusion of heat, enabling the metal particles to melt and solidify uniformly. This controlled heating process eliminates any potential defects and ensures the final product possesses exceptional thermal homogeneity. This integrity enhances the component's resistance to thermal stress, making it suitable for high-temperature applications.

3. Dimensional Precision: The sintering process in metallurgy allows for intricate shaping and complex geometries. Through powder metallurgy, we are able to create precise components with close tolerances and high dimensional accuracy. This ensures that the final product fits seamlessly into your application, reducing the need for subsequent machining processes.

4. Tailored Material Properties: Our sintering process offers the flexibility to modify material properties according to your specific requirements. By incorporating different alloying elements during the powder formulation stage, we can fine-tune properties such as hardness, corrosion resistance, and electrical conductivity. This customization capability allows us to provide you with a product that perfectly aligns with your application needs.

Benefits for the Customer:

1. Enhanced Performance: Our sintered components exhibit unparalleled performance due to their increased strength, improved wear resistance, and exceptional thermal conductivity. With our products, you can confidently tackle demanding applications knowing that they will withstand the toughest conditions.

2. Extended Product Lifespan: By undergoing the sintering process in metallurgy, the components gain superior durability, increasing their lifespan. This translates into reduced maintenance and replacement costs, ensuring a higher return on investment for our customers.

3. Versatility and Adaptability: Thanks to the dimensional precision achieved through our sintering process, our components can be seamlessly integrated into various applications. Whether it's automotive, aerospace, or industrial machinery, our products offer versatile solutions that meet diverse industry requirements.

4. Tailored Solutions: We understand that every application demands specific material properties. Our sintering process allows us to create tailor-made components precisely engineered to meet your needs. This customization ensures that you receive a product that perfectly aligns with your performance expectations.

Experience the Excellence of Sintering:

Our sintering process in metallurgy brings forth a new era of strength, durability, and versatility. With our expertise in crafting components with exceptional material properties, you can trust us to deliver high-performance solutions that exceed your expectations. Embrace the benefits of our sintered products and achieve new heights in your applications.

If you want to learn more, please visit our website what is sintering in metallurgy, china metal square can, sintered bronze filter disc.