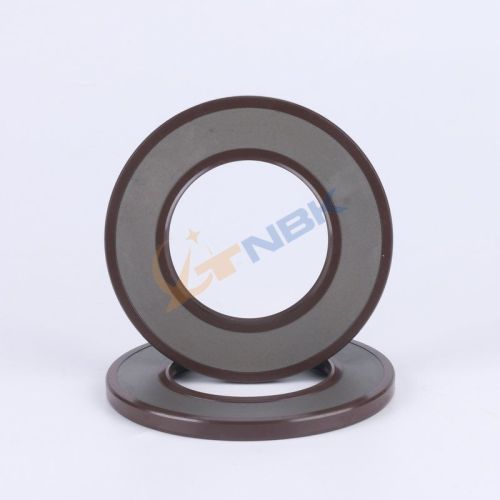

Hydraulic Motor Seal TCV Oil Seal

Hydraulic Motor Seal TCV Oil Seal

Product Description

Types of hydraulic cylinder oil seals

Hydraulic cylinder oil seals are mainly divided into two categories: one-way oil seals and two-way oil seals. The one-way oil seal includes U-shaped oil seals and V-shaped oil seals, while the two-way oil seal includes combination oil seals and Y-shaped oil seals.

1. U-shaped oil seal

U-shaped oil seal, also known as cup shaped oil seal, has a shape similar to a "U" shape and is composed of three parts: inner ring, outer ring, and sealing lip. U-shaped oil seals are mainly used at the end of the piston rod of hydraulic cylinders.

2. V-shaped oil seal

A V-shaped oil seal is composed of multiple components such as an inner ring, an outer ring, a spring, and a sealing lip. Its appearance is similar to the letter "V" and can be divided into two types: large caliber and small caliber. Compared to U-shaped oil seals, V-shaped oil seals have better sealing performance and are more suitable for high-speed and high-temperature working environments.

3. Combination oil seal

A combination oil seal is composed of two V-shaped oil seals and an O-ring. It can simultaneously achieve bi-directional sealing of hydraulic cylinders, also known as "bi-directional oil seals".

4. Y-shaped oil seal

Y-shaped oil seal is a new type of hydraulic cylinder oil seal, which has a shape similar to a "Y" shape. It can achieve bi-directional sealing of hydraulic cylinders, and compared to combination oil seals, Y-shaped oil seals have higher sealing performance and longer service life.

The selection method of hydraulic cylinder oil seal

1. Select according to pressure level

The pressure level of the hydraulic system is an important indicator for oil seal selection, and usually the oil seal supplier will provide the maximum pressure value it can withstand in the product manual. Therefore, when selecting oil seals, it is necessary to choose the appropriate oil seal model based on the pressure level of the hydraulic system.

2. Choose according to the working environment

The working environment of hydraulic cylinders usually has high temperatures, significant impact forces, etc. Therefore, it is necessary to choose the appropriate oil seal material based on the working environment of the hydraulic cylinder. For example, hydraulic cylinders operating in high-temperature environments should use high-temperature resistant oil seals.

3. Select according to the working mode of the hydraulic cylinder

The working mode of hydraulic cylinders is divided into two types: one-way and two-way, so it is necessary to choose one-way oil seal or two-way oil seal according to the working mode of the hydraulic cylinder. When selecting oil seals, it is necessary to pay attention to matching the size of the oil seal with the size of the hydraulic cylinder.

Hydraulic oil seals are used in a wide range of applications, including industrial machinery, construction equipment, and automotive systems. They are essential in hydraulic cylinders, pumps, valves, and other components that require hydraulic oil transmission. Seals ensure smooth and efficient operation of the system without any leaks or malfunctions.

Hydraulic oil seals are an important component of hydraulic systems. They play a crucial role in maintaining hydraulic oil pressure and flow, preventing leaks and malfunctions. The sealing design can withstand high pressure, extreme temperatures, and chemical corrosion, ensuring a longer service life of the system. They are also easy to install and replace, reducing downtime and maintenance costs. Hydraulic oil seals have functional and environmental advantages, making them an important component of modern hydraulic systems.