plastic injection moulding advantages and disadvantages

Title: Explore the Advantages and Disadvantages of Plastic Injection Moulding for Unparalleled Manufacturing Solutions!

Product Description

Title: Explore the Advantages and Disadvantages of Plastic Injection Moulding for Unparalleled Manufacturing Solutions!

Subtitle: Unveiling the Brilliance of Plastic Injection Moulding - Enhance Efficiency, Quality, and Precision!

Are you ready to unlock the potentials of manufacturing with plastic injection moulding? Look no further because our cutting-edge technology and expertise are here to revolutionize your production process! Discover the advantages and disadvantages of plastic injection moulding and make an informed decision that will elevate your business to new heights!

1. Advantages of Plastic Injection Moulding:

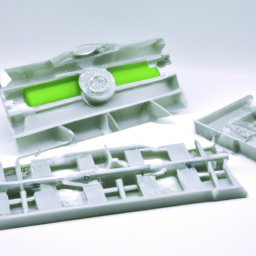

1.1 Superior Precision and Complex Geometry:

With plastic injection moulding, intricate and complex designs can be effortlessly achieved. Our state-of-the-art equipment enables you to create parts with impeccable precision, ensuring consistent quality with every production run. Say goodbye to limitations and embrace the endless possibilities of intricate product designs!

1.2 Cost-Efficiency and High Production Rates:

Plastic injection moulding offers remarkable cost savings for high-volume production runs. By utilizing automated processes, reduced labor costs, and minimized material wastage, you can optimize your manufacturing efficiency and achieve economies of scale like never before. Elevate your profitability by producing more while spending less!

1.3 Vast Material Options:

Choose from a wide array of materials, including thermoplastics, to fulfill your product's specific requirements. From durable and lightweight options to specialized materials with enhanced characteristics, we offer versatility to meet your industry's demands. Achieve product excellence by selecting the perfect material for its intended purpose.

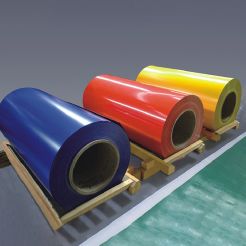

1.4 Strength, Durability, and Color Variety:

By leveraging plastic injection moulding, you can enjoy superior product strength and durability, ensuring longevity and endurance. Our process enables the creation of vibrant, consistent, and customizable product colors, enhancing your brand's identity and offering an aesthetic appeal that captures your customers' attention.

2. Disadvantages of Plastic Injection Moulding:

2.1 High Initial Tooling Costs:

The initial tooling costs associated with plastic injection moulding might pose a challenge for lower volume production runs. However, the cost becomes relatively insignificant when considering long-term, high-volume production, as it guarantees exceptional quality and reduced unit costs. Minimize the initial impact by planning for future growth and optimization!

2.2 Design Limitations:

While plastic injection moulding can create complex designs, some limitations may arise, such as draft angles and other structural constraints. Collaborate with our experienced engineering team to leverage their expertise and overcome potential design hurdles, ensuring your vision becomes a reality.

2.3 Potential Part Imperfections:

Plastic injection moulding may occasionally result in minor imperfections, such as sink marks or small cosmetic defects due to material flow and cooling variations. However, our rigorous quality control processes and experienced technicians ensure that these issues are minimized to guarantee exceptional product quality.

3. Experience the Future of Manufacturing:

Discover the unparalleled advantages of plastic injection moulding and unlock the true potential of your manufacturing endeavors. With our state-of-the-art machinery, expertise, and commitment to excellence, we ensure that your vision becomes a reality. Revolutionize your industry, enhance your brand, and exceed your customers' expectations with our exceptional plastic injection moulding solutions!

Invest in the future. Experience perfection. Choose plastic injection moulding for unparalleled manufacturing success!

Whether you are a seasoned industry professional or a passionate entrepreneur, our expert team is ready to guide you through the process, answer your questions, and support you every step of the way. Contact us today and embark on a journey towards manufacturing excellence!

Want more information on quick turn cnc machining, oem rapid injection molding factories, wintech manufacturing co. ltd? Feel free to contact us.