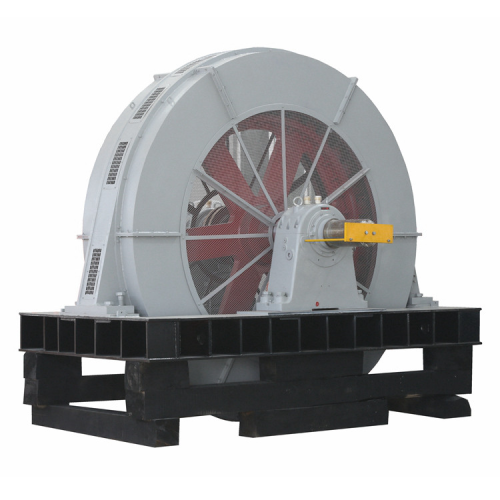

Large synchronous electric motor

The stator of the large high-voltage synchronous motor is made of public cooling and rolling non-oriented silicon steel sheets, which are laminated and pressed.

Product Description

The large synchronous motor is a horizontal three-phase salient-pole synchronous motor. The installation method of the motor is horizontal installation. The outer casing of the motor has a circular structure, the protection grade is IP20, and the cooling mode is open ventilation cooling.

Working Principle

This series of large synchronous motor excitation systems uses thyristor excitation devices.

The high voltage large synchronous motor allows full voltage to be started directly. If the user's power grid does not allow the full voltage to start directly, the step-down start can also be used. At this time, the starting current of the motor decreases in proportion to the terminal voltage, and the starting torque decreases in proportion to the square of the terminal voltage.

This type of large synchronous motor front and rear bearings use seated sliding bearings, the bearing is equipped with a pressure thermometer, transparent cover oil. Check holes for easy oil filling and oil mist spillage. The slip ring assembled by the motor is fixed to the non-axial extension end of the main shaft and is coaxial with the main shaft. The jump is small and easy to overhaul. The slip ring brush holder is fixed to the seat block of the non-shaft end. Motor bearings, winding temperature measurement and heating devices can also be added according to customer requirements.

Product Name: Large Synchronous Excitation Electric Motor

Rated voltage: 3000V, 6000V, 10000V, 13800V

Capacity range: 500 kW ~ 6000kW

Rated frequency: 50Hz, 60HZ

Cooling method: IC01, IC81W

Quota: S1

Synchronous speed: 150-1500r/min

Insulation class: Class F

Temperature rise level: B

Connection: Y

Protection level: IP00/IP21/IP23

Power factor: 0.9 (leading)

Excitation mode: static thyristor (other excitation methods can also be made)

Altitude: no more than 1000m

This large-scale high-voltage synchronous motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

If you want to buy large synchronous motor, please feel free to contact us.

Large high-voltage synchronous motors have large moment of inertia characteristics and are widely used in petroleum. Chemical, electric power and other industries are used to drive loads with large moments of inertia such as fans, pumps and compressors.

This series of motors adopts new technology, new materials, new technology, colorful and exquisite, well-made, specific small size, light weight, high efficiency, low noise, low vibration, safe and reliable operation, convenient use and maintenance. The motor has an advanced power factor (which improves grid power factor), high efficiency, high stability and high overload capability, and has the performance that the speed does not change with load.

Structure

1.The stator of the large high-voltage synchronous motor is made of public cooling and rolling non-oriented silicon steel sheets, which are laminated and pressed. The frame is a structurally strengthened steel plate welded structure that effectively avoids the effects of natural frequencies.

2.The stator winding of the large synchronous motor adopts the star connection method, and the six line ends are led out. The main lead ends are marked U1, V1, W1, and the neutral point leading end marks U2, V2, W2. The end of the stator coil is fastened with a polyester sleeve, and is tightly integrated with the end hoop and the support member (insulating member). It has reliable insulation performance and strong anti-vibration and moisture resistance. And through the overall VPI dipping process, the temperature rise of the motor is reduced, and the performance index and operational reliability of the motor and insulation are improved.

3.After the VPI, the coil and the iron core are integrated, the bonding is firm, the mechanical strength of the whole winding is obviously enhanced, and the motor is greatly improved in moisture resistance, water resistance and environmental pollution resistance.

4.The large high-voltage synchronous motor has a cylindrical shaft extension end, and its rotation direction should be rotated in the direction specified by the sign. The rotation direction is generally counterclockwise from the end of the collector ring, and can also be made clockwise according to requirements. When the motor and the mill are coupled by a coupling, the motor shaft cannot be extended to withstand external radial or axial forces.

The high-voltage synchronous motor has large moment of inertia characteristics and is widely used in mining, petroleum, chemical, electric power and other industries for dragging and unloading loads of large moments of inertia such as fans, pumps, compressors, and mills.

Related News

Advantages and Applications of Slip Ring Induction Motors

Application of Synchronous Motors

What are Synchronous Motors and how they work

Advantages and Use of Medium - High Voltage Motors

Synchronous and Asynchronous Motors-Where Are They Used?

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

Our service advantage

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6, Good faith and mutual benefit, good credit guarantee.