Fiberglass Filter Cap For Aluminium Liquid

Custom-made fiberglass filter caps for aluminum liquid filtration. Enhance your casting process with precision-designed fiberglass caps, ensuring purity and quality in molten aluminum. Explore our range for tailored solutions.

Product Description

The Fiberglass Filter Cap-style is woven with special high-twist & high-strength alkali-free fiberglass yarn, carbonized by high temperature and coated with special resin, then after special post-treatment.

● The max. temperature resistance can be reached 900 ℃

● Smokeless & Odorless & Flameless during whole filtration process

● With one or two staples or not, up to clients' need

● Individual custom-made products according to client's drawing and samples

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

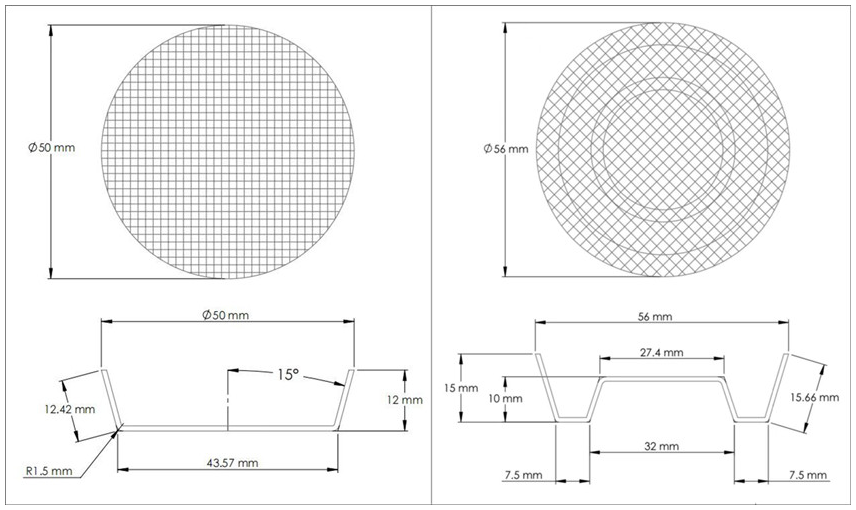

Parameter

Engineered to meet the unique demands of your aluminum casting process, our Fiberglass Filter Caps stand as a testament to quality and innovation. With a focus on individual customization, we take pride in delivering custom-made Fiberglass Filter Caps that seamlessly integrate into your production setup.

As a filter equipment often used in industrial production, Fiberglass Filter Cap plays an important role in metal smelting industry. Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Individual custom-made Fiberglass Filter Cap according to client's drawing and samples.

| Type | Fiberglass Cap Filter For Aluminum |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| Gas Emit | ≤30cm 3/g |

| Thickness | 0.5mm |

| Weight | 150-350 g/m2 |

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

| Weave Pattern | Leno |

| Certificate | ISO9001:2015 |

Whether you're operating in the realm of automotive manufacturing, aerospace engineering, or any industry that relies on clean and high-quality aluminum products, our custom-made Fiberglass Filter Caps offer the perfect solution. They effectively capture impurities, ensuring that only the purest molten aluminum flows through your casting process.

Functions:

● Effectively remove impurities

● Reduce turbulence and eliminate air bubbles

● Improve the quality of castings and reducing costs

● Does not pollute the aluminum liquid

● Does not affect the chemical properties of the metal

● Aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting

What sets our Fiberglass Filter Caps apart is their exceptional durability and heat resistance. As the molten aluminum flows through these caps, their robust construction stands up to the extreme temperatures, maintaining their structural integrity and efficiency over extended use.

Position of Fiberglass Filter Cap:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Why are Fiberglass Filter Caps so widely used?

First of all, the product characteristics are one of the important factors affecting the development of cap filter manufacturers.

Secondly, because of the shortage of resources, it is imperative to reduce the waste of resources in the metal industry. Through the use of cap filter, which can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, also the main trend.

Thirdly, it can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. Through the use of filter can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.Learn more.

Our Service: Individual custom-made products

Materials: Client's drawing and samples

Mould: Produced by us

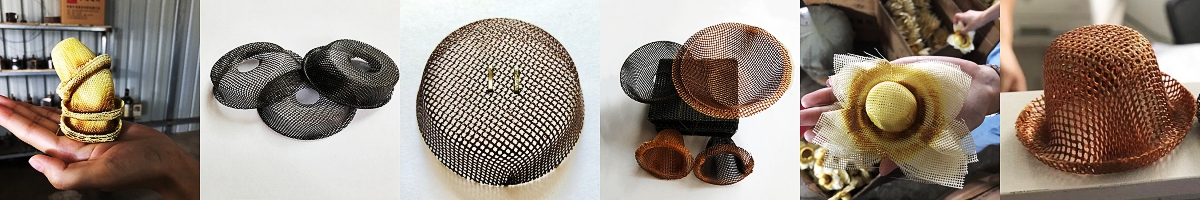

Shapes: The shapes of filter screen products are: rectangle, square, circle, ellipse, ring, rectangle, hat, waist, and special-shaped

Types: single-layer, double-layer, and multi-layer

Produce process: The different shapes of the filter mesh, and the technology is also different

Individual custom-made Fiberglass Filter Caps for our clients from all over the world:

Invest in the future of your aluminum production with our Fiberglass Filter Caps. Each cap is a testament to our commitment to delivering tailored solutions that elevate your manufacturing process. Experience the difference of custom-made excellence – choose our Fiberglass Filter Caps for unparalleled performance and reliability.Contact Now!

Application:

Impurity Filtration: The primary purpose of the Fiberglass Filter Cap is to ensure the purity of molten aluminum. It effectively captures impurities, such as oxides, slag, and non-metallic particles, preventing them from contaminating the aluminum during casting and other manufacturing stages.

Quality Assurance: By effectively filtering out impurities, the filter cap significantly improves the quality of the final aluminum products. This translates into enhanced mechanical properties, improved surface finish, and fewer defects in the end products.

Process Efficiency: The use of the Fiberglass Filter Cap optimizes the casting process. It minimizes the risk of clogs, blockages, and disruptions caused by impurities, allowing for smoother and more efficient aluminum flow through the casting system.

Reduced Waste: With impurities captured by the filter cap, there's a notable reduction in waste and scrap aluminum. This not only positively impacts production costs but also contributes to a more sustainable manufacturing process.

Extended Equipment Life: By preventing the entry of harmful particles, the filter cap helps protect casting molds, machinery, and other equipment from potential damage. This extends the lifespan of critical equipment and reduces maintenance requirements.

Consistency in Alloy Composition: The Fiberglass Filter Cap ensures consistent alloy composition by preventing unwanted elements from entering the molten aluminum. This is particularly crucial in industries where specific alloy compositions are vital for desired properties.

Enhanced Safety: The filter cap enhances workplace safety by reducing the presence of airborne particles and contaminants that could pose health risks to workers in the vicinity of the aluminum processing area.

Wide Industry Applicability: The uses of the Fiberglass Filter Cap extend across diverse industries that rely on aluminum, including automotive, aerospace, construction, and more. It caters to a broad spectrum of applications, ensuring clean and high-quality aluminum products across various sectors.