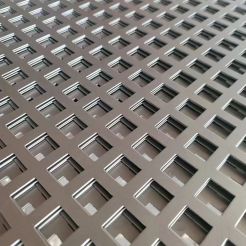

85% Undensified Silica Fume

Silica fume is a byproduct of producing silicon metal or ferrosilicon alloys. It consists primarily of amorphous silicon dioxide (SIO₂), its average granule diameter is 0.15~0.20 μm, specific surface area is 15000~20000 m²/kg. Metal Silicon Powder is mainly used for high transparency, high resistance to tear silicone rubber, silicone grease, sealed packaging materials such as capacitors.

Product Description

•SiO₂: >85%

•Color: Light Grey

•PH Value: 5~8.5

•Category: Undensified Silica Fume

•Bulk density: 240-270kg/m³, 320kg/m³

•Packages:25kg plastic woven bags, 500kg plastic woven bags, 600kg plastic woven bags,1000kg plastic woven bags.

85% Undensified Silica Fume is a micro silica fume with 85% SIO₂ content, and the Bulk density is 240-320kg/m³.

Silica fume is a byproduct of producing silicon metal or ferrosilicon alloys. It consists primarily of amorphous silicon dioxide (SIO₂), its average granule diameter is 0.15~0.20 μm, specific surface area is 15000~20000 m²/kg. Metal Silicon Powder is mainly used for high transparency, high resistance to tear silicone rubber, silicone grease, sealed packaging materials such as capacitors.

Tags: 85 Microsilica,85U Silica Fume,85 Grade Silica Fume,85% Undensified Silica Fume Archives

85% Undensified Silica Fume Advantages

. Lowers concrete permeability.

. Significantly increases concrete durability.

. Increases ultimate strength gain.

. Beneficial in all types of high-strength concrete applications.

. Improves bond strength to steel.

. Significantly reduces alkali-silica reactivity.

. Provides excellent resistance to sulfate or seawater attack.

. Reduces steel corrosion.

. Improves freeze/thaw durability of concrete.

Please Note:

. In the application of high-strength, high abrasion resistance, underwater casting of anti-scattering concrete, etc., the amount of silica fume admixture should not be too low usually accounting for 5%-10% of the cementitious material.

. Use 85% Undensified Silica Fume preparation of high-strength, early-strength concrete should be used with the high-efficiency water-reducing agent, with high-strength concrete should be selected with the low air-entraining high-efficiency water-reducing agent, depending on the situation can add defoamer.

. In ordinary strength, impermeable, highly durable or self-compacting concrete applications, it is appropriate to use a multi-component cementitious material with low silica fume admixture, usually accounting for 2%-5% of the cementitious material.

. The addition of 85% Undensified Silica Fume needs to extend the mixing time, and can not be mixed in wet concrete after mixing, it is recommended to extend the mixing time to 30 seconds than ordinary concrete to ensure uniform mixing.

. Plastic shrinkage crack sensitive, better maintenance method is: spraying concrete that has not yet set, spraying curing agent maintenance; concrete hardening, the use of maintenance film, covered with wet sacks or plastic film.

85% Undensified Silica Fume Parameters

85% Undensified Silica Fume is produced in conformance with the ISO9001:2008 quality management system. The quality is controlled and monitored throughout the entire production process to ensure that it meets or exceeds specification requirements.

| National Standards for Silica Fume for Concrete | ||||||||||

| National Standards and Organizations | Europe | Norway | France | Australia | United States | Canada | Japan | China | ||

| Standard Code | CEN EN | NS | NF | AS | ASTM C | CSA | JIS | GB/T | GB/T | |

| Standard Number | 13263 | 3045 | P18-502 | 3586 | 1240 | A23.5 | A6207 | 18736 | 27690 | |

| SiO2 % ≥ | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | |

| SO3 % < | 2 | 2.5 | 3 | 1 | 3 | |||||

| CI- % < | 0.3 | Report | 0.2 | Report | 0.1 | 0.1 | 0.1 | |||

| CaO % < | 1 | 2 | 1 | |||||||

| MgO % < | 5 | |||||||||

| Si % < | 0.4 | 0.4 | ||||||||

| Na2O+K2O % < | 4 | 1.5 | ||||||||

| C % < | 4 | |||||||||

| Water Content % < | 2 | 3 | 3 | 3 | 3 | |||||

| Burn Vector % < | 4 | 5 | 6 | 6 | 6 | 5 | 6 | 4 | ||

| Specific Surface Area ㎡/g | 15-35 | ≥12 | 20-35 | ≥15 | ≥15 | ≥15 | ||||

| 45μm Sieve Residue % < | 10 | 10 | 5 | |||||||

| Loose capacity kg/m³ | Report | Report | ||||||||

| Specific Gravity g/㎝³ | 2.1-2.3 | Report | ||||||||

| Water Demand Ratio % ≤ | 125 | 125 | ||||||||

| Volcanic Ash Activity Index | %(3d) ≥ | |||||||||

| %(7d) ≥ | Report | 105 | 85 | 85 | 95 | 105 | ||||

| %(28d) ≥ | 100 | 95 | 100 | 115 | ||||||

| Water to Glue Ratio | 0.5 | 0.5 | 0.484 | 0.5 | 0.5 | 0.5 | ||||

| Conservation | Standard | Standard | Accelerated | Accelerated | Standard | Standard | Accelerated | |||

85% Undensified Silica Fume Application

Concrete, Refractory, High Performance Concrete, Oil and Gas Industry, Ceramics, Concrete Roofing, Wall boards, Cementation Repair Products, Concrete Tile & Panels, FCB, Shotcrete, Polymers & Elastomers and (SCC) Self-Compacting Concrete.