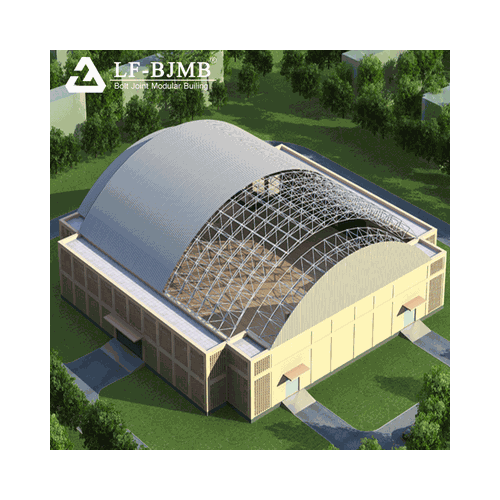

Prefab Metal Truss Gym Roof Steel Structure Sport Hall for Sale

Product Description

Payments:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Delivery:10

Origin:jiangsu

Packing:-

Inspection:-

Sample Price:$0.01

Prefab Metal Truss Gym Roof Steel Structure Sport Hall for Sale

For more project information, visit our website for consultationhttps://www.cnxzlf.com/

Project name | China Prefab Metal Building Roofing Trusses Construction Projects badminton Sports Hall Stadium Roof Canopy Structure |

Wind load | 250kph |

Seismic load | 4(Z=0.4) |

Steel material | Q235B/Q345B,45#,40Cr |

Certificate | ISO, CE, SGS |

Cladding system | Color steel sheet with PVDF finish treatment & FRP natural lighting roof sheet |

Delivery period | 35~40 Days |

Project installation service | Engineers on-site installation guide. |

Warranty | 1 year |

Manufacturing Technique

FACTORY PROCESSIING SHOW

The modernization of professional steel structure production process.

It can meet a variety of production needs and temporary large-scale operation needs

Product packaging

Packing & Transportation

* Every LF structural member gets a sticker with identifying information. Unique mark, component number, fabrication. parameters, and QR coding ensure that all component information is available exactly when and where required.

* Small parts packed in a wood carton.

* Big parts packed by a steel frame which is convenient for container unloading by fork lift or crane on site.

* Delivery Goods in the factory and transported to seaport by truck.

* All goods will be loaded into the container at port warehouse.

Why Choose Us