plastic injection moulding advantages and disadvantages

[Title]: Unlocking Tremendous Possibilities with Plastic Injection Moulding.

Product Description

[Title]: Unlocking Tremendous Possibilities with Plastic Injection Moulding.

[Subtitle 1]: Revolutionize Manufacturing with Unparalleled Precision and Efficiency.

Are you ready to embark on a transformative journey in manufacturing? Look no further than plastic injection moulding! With its multitude of advantages and a few considerations to keep in mind, this cutting-edge technology redefines the boundaries of what is possible. Get ready to witness the astounding benefits it brings to your business and discover how it can make your customers' lives even more delightful.

[Subtitle 2]: Advantages that Bring Your Vision to Life.

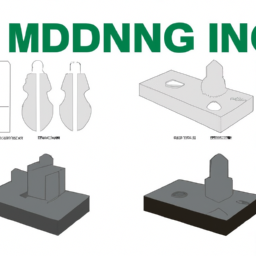

1. Impeccable Precision: Every intricate detail and delicate contour of your product becomes a reality with plastic injection moulding. Get ready to surpass your customers' expectations by delivering flawless components that fit together seamlessly. From microcomponents to large structures, embrace the accuracy that will leave your competitors in awe.

2. Enhanced Efficiency: With its swift production process, plastic injection moulding optimizes your manufacturing capabilities like never before. Mass production has never been easier! Meet increased demand while minimizing costs, thanks to the streamlined automation and minimized post-processing required. Boost your productivity and ride the wave of success.

3. Versatile Material Selection: With a wide range of material options at your disposal, plastic injection moulding allows you to select the perfect match for your desired outcome. From the flexibility of polypropylene to the durability of polycarbonate, the possibilities are endless. Cater to specific requirements and ensure the longevity of your products.

4. Freedom of Design: Unleash your creativity without limitations! Plastic injection moulding liberates you from design constraints, giving you the freedom to explore limitless shapes, textures, and sizes. Create captivating products with smooth finishes, bold colors, and ergonomic forms, all while maintaining structural integrity. Be the visionary your customers deserve.

[Subtitle 3]: Considerations for Optimal Decision-making.

1. Initial Investment: While the benefits of plastic injection moulding are vast, it's important to consider the initial investment required. The design and manufacturing of molds can be costly. However, this should be viewed as an investment that unlocks long-term success, allowing for high-volume production and enhanced profitability.

2. Time for Mold Creation: Keep in mind that the creation of molds requires meticulous precision and time. It's essential to allocate enough time in your production timeline for mold design and creation. Patience is rewarded with exceptional outcomes.

3. Complexity of Design Changes: Once the mold is created, any design changes can be challenging and costly. Therefore, it's essential to thoroughly evaluate and fine-tune your product design before proceeding with plastic injection moulding. Ensure every detail is precisely as desired and embrace the benefits of consistency.

[Subtitle 4]: Elevate Your Business to New Heights.

Dive into the realm of possibilities that plastic injection moulding offers. Embrace impeccable precision, enhanced efficiency, versatile material selection, and the freedom to design beyond imagination. Create products that will captivate your customers and make their lives easier, showcasing your commitment to quality.

While initial investments and mold creation require careful consideration, the long-term benefits outweigh any challenges. Unlock the power of plastic injection moulding and witness your business soar to new heights of success.

[CTA]:

Join the countless industry leaders who have harnessed the immense potential of plastic injection moulding. Discover how your vision can become a reality today. Upgrade your manufacturing prowess and witness the unmatched benefits that only plastic injection moulding can deliver.

Want more information on quick turn cnc machining, oem rapid injection molding factories, wintech manufacturing co. ltd? Feel free to contact us.