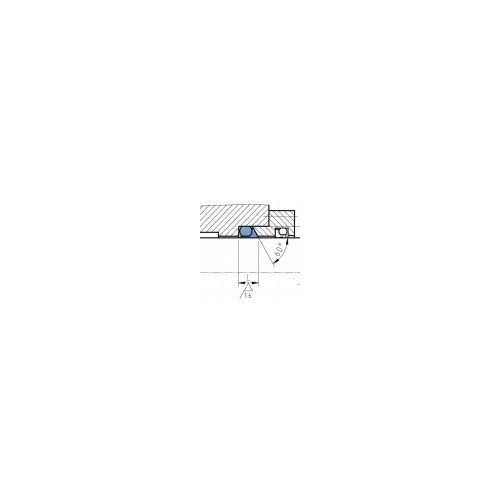

slip ring seal

A slip ring seal is a type of mechanical sealing device used to prevent fluid or gas leakage in rotating machinery. I

Product Description

https://www.jk-seals.com/product/foot-shape-slip-ring-combined-seal-slip-ring-combined-seal/

A slip ring seal is a type of mechanical sealing device used to prevent fluid or gas leakage in rotating machinery. It is typically used in equipment with rotating shafts, such as electric motors or generators, to provide a seal around the rotating shaft and prevent the leakage of fluids or gases from one side of the seal to the other. A slip ring seal is typically made up of a stationary component and a rotating component, and is designed to maintain a sealing interface as the shaft rotates.

Performance and Purpose

Slip ring combined seal is made up of low-friction PTFE composite slip ring and O-ring. It has the advantages of friction resistance, temperature resistance, high pressure bearing ability, high linear velocity, small friction force and long use-life. And which is applicable to dynamic and static seal of hydraulic and pneumatic system in aircraft, metallurgy, petroleum, chemical, textile, food industry and so on.

Advantage

The structure is simple, easy to install and can be used repeatedly

The sealing performance is reliable and adjustable

Different types of PTFE materials(Self pressed PTFE barrel material)can be selected according to the working conditions of sealing environment

The working life of dynamic pressure seal is 5 ~ 10 times higher than that of conventional rubber sealing products, and the highest working life can reach dozens of times

It can be used as oil-free lubrication seal

The friction force is small, and the dynamic and static friction force are equal. The friction force is 1 / 2 ~ 1 / 4 of the O-type rubber ring, which can eliminate the “crawling” phenomenon of motion at low speed and low pressure.

If you are looking for more details, kindly visit our website.