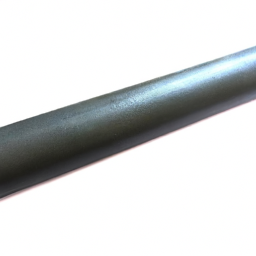

UHP Graphite Electrodes

UHP Graphite Electrodes

Product Description

Graphite electrode are manufactured with high quality raw materials including petroleum cokes, needle cokes and coal tar pitch through the production processes of calcining, crushing, screening, dosing, kneading, extruding, baking, impregnation, graphitization, machining. Our products are characterized by superior compact structure, good electrical and thermal conductivity, high mechanical strength and high resistance to oxidation and corrosion in high tempertature. The graphite electrode are widely used in electric arc furnace and ladle refining furnaces foe steel making and used in ore smelting furnace for producing industrial silicocn,yellow phosphorus, corundum, nonmetals and so on, it is one essential part of the raw material industry.

UHP Graphite Electrodes: Wide Applications Across Industries

Steel Manufacturing:

Electric Arc Furnaces (EAFs): UHP graphite electrodes are critical in EAFs for steel production. They provide the necessary conductivity and heat resistance to melt scrap steel and other raw materials efficiently.

Ladle Furnaces (LFs): In ladle furnaces, UHP electrodes are used for refining molten steel, adjusting its temperature, and ensuring the desired chemical composition.

Non-Ferrous Metal Production:

Smelting and Refining: UHP graphite electrodes are used in the smelting and refining processes of non-ferrous metals such as aluminum, copper, and zinc. Their high power capacity ensures efficient melting and purification.

Chemical Industry:

Electrolysis: UHP electrodes serve as anodes or cathodes in electrolytic cells, facilitating the production of chemicals like chlorine, caustic soda, and hydrogen.

Silicon and Ferroalloy Production:

Submerged Arc Furnaces (SAFs): In the production of silicon and ferroalloys, UHP graphite electrodes are employed in SAFs to provide the necessary electrical energy for high-temperature reactions. More contact Zhongsheng Carbon

Foundries:

Melting and Casting: Foundries use UHP graphite electrodes in electric furnaces for melting various metals and alloys. These electrodes help achieve precise temperature control and high-quality metal casting.

Refractory Materials:

Manufacturing: UHP graphite electrodes are used in the production of refractory materials, which are essential for lining furnaces, kilns, and reactors due to their high resistance to heat and wear.

Semiconductor Industry:

Crystal Growth:

UHP graphite electrodes are utilized in the Czochralski (CZ) process for growing high-purity silicon crystals, which are crucial for manufacturing semiconductors and photovoltaic cells.

Energy Storage:

Battery Production: UHP graphite electrodes are being explored for use in advanced battery technologies, including lithium-ion batteries, where their high conductivity and stability can enhance battery performance.

Tags: HP Graphite Electrodes, UHP600 Graphite Electrodes, UHP700 Graphite Electrode

UHP Graphite Electrodes Allowable Current-Carrying Capacities

|

Nominal |

UHP Graphite Electrodes |

||

|

mm |

inch |

Current-Carrying Capacity(A) |

Current Density(A/cm²) |

|

350 |

14 |

20000-30000 |

20-32 |

|

400 |

16 |

25000-40000 |

20-32 |

|

450 |

18 |

32000-45000 |

20-30 |

|

500 |

20 |

38000-55000 |

20-30 |

|

550 |

22 |

48000-60000 |

18-24 |

|

600 |

24 |

52000-72000 |

18-24 |

|

650 |

26 |

60000-85000 |

18-24 |

|

700 |

28 |

62000-95000 |

18-24 |

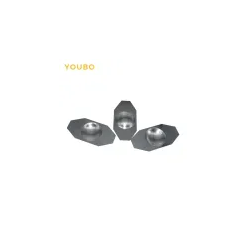

Dimensions Drawing Of Taper Nipples

Recommended Tightening Torque