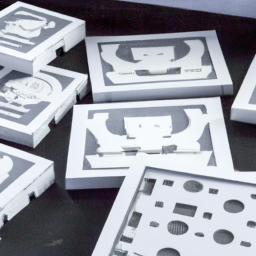

Ceramic Fiber Module

Ceramic Fiber Module is produced from Ceramic Fiber Blanket that is accordion-folded or stacked, and pre-compressed to form rectangular modules. This modular design features non-exposed anchoring which aids in an economical installation and mechanical attachment. Attachment mechanisms are available in various alloys or through the use of ceramic cuplocks.

Product Description

Additionally, our modules come in a pre-weld or shoot-on application form for differing installation methods. Modules are great solutions for thick-walled high-temperature insulation needs in various industries such as Heat Treating, Iron & Steel, Refining & Petrochemical, Power Generation, and Ceramics.

Specification:

Modules can be manufactured in various densities, sizes. Standard size is 300x300x300mm, 250x300x300mm,200x300x300mm.

Classification

Ceramic fiber modules can be divided into the following types according to the temperature grade

1050 ordinary ceramic fiber module

1260 standard ceramic fiber module

1260 high purity ceramic fiber module

1400 high aluminum ceramic fiber module

1400 Low Zirconium Ceramic Fiber Module

1430 Zirconium-containing ceramic fiber module

Technical Data sheet

|

Type |

STD Module |

HP Module |

HZ Module |

|

|

Classified Temperature |

1260℃ (2300℉) |

1260℃ (2300℉) |

1430℃ (2606℉) |

|

|

Working Temperature |

1050℃ (1922℉) |

1100℃ (2012℉) |

1350℃ (2462℉) |

|

|

Density(kg/m3) |

160-260 (13-16 lb/ft3) |

|||

|

Linear Shrinkage 24hrs |

≤2.5 1000℃/2012℉ |

≤2.5 1100℃/2012℉ |

≤3.5 1350℃/2462℉ |

|

|

Thermal Conductivity(W/m.k) |

400℃ (752℉) |

0.09 |

0.101 |

0.118 |

|

500℃ (930℉) |

0.119 |

0.12 |

0.149 |

|

|

|

600℃ (1112℉) |

0.152 |

0.175 |

0.195 |

|

Chemical Composition % |

Al2O3 |

≥44 |

≥45 |

≥34 |

|

SiO2 |

≥52 |

≥54 |

≥50 |

|

|

ZrO2 |

|

|

≥15 |

|

|

Fe2O3 |

≤1.0 |

≤0.5 |

≤0.5 |

|

|

K2O+Na2O |

≤1.0 |

≤0.2 |

≤0.2 |

|

|

Packing |

plastic bag together with Carton or Pallet |

|||

APPLICATIONS

Industrial Heaters and Furnaces

Boilers and Incinerators

Tunnel Kilns

Reformer, Ethylene, and Pyrolysis Furnaces

Stack and duct linings.

Soaking pit covers and seals

Email: ecoinsulation@126.com

Mob.: +86 137 0316 9121

WeChat: +86 137 0316 9121

Whatsapp: +8613703169121

Add.: Internaltion Enterprise Community, Changyuan Road, Wuqing, Tianjin